Positive Comments: Digital Systems Are Key Tools for Enterprise Transformation, and Strategic Emphasis Can Unleash Breakthrough Value

The essence of a digital system is a tool, but the value of this tool far exceeds what an “ordinary tool” can represent. It is the core support for enterprises to reconstruct business logic and improve management efficiency in the digital age. From a technical perspective, whether it is the ERP (Enterprise Resource Planning) system that integrates resources in procurement, production, sales and other links, the CRM (Customer Relationship Management) system that precisely manages the entire customer lifecycle, or the MES (Manufacturing Execution System) that monitors the production process in real – time, their core functions are to optimize business processes through data – driven and automated means, shifting enterprises from the traditional “experience – driven” to “data – driven”. The value of this tool attribute has been verified by a large number of practices in the correct application scenarios: A certain automobile manufacturing enterprise shortened its inventory turnover cycle from 45 days to 20 days and increased the accuracy of production plans by 30% through deploying a customized ERP system; A certain retail enterprise relied on the CRM system to integrate online and offline customer data, achieving a 25% increase in the membership repurchase rate. These cases fully demonstrate that when enterprises regard digital systems as tools “serving business”, their effectiveness can be directly translated into improved operational efficiency and reduced costs.

What is even more noteworthy is that when enterprises regard digital systems as “artifacts for breakthrough innovation” at the strategic level, their value may go beyond the tool itself and become the core engine driving organizational change. For example, a leading home appliance enterprise deeply integrated the digital system with the “Customer – to – Manufacturer (C2M)” model. By using the system to capture user demand data in real – time, it reversely drove the adjustment of R & D, production and supply chain. This not only increased the product customization rate from 10% to 40%, but also promoted the enterprise’s transformation from a “manufacturing enterprise” to a “service – oriented manufacturing enterprise”. This breakthrough is the result of enterprises regarding the system as a “strategic – level tool”. It is no longer just an efficiency optimizer for a single link, but a key carrier connecting users and reconstructing business models.

From the perspective of industry trends, the tool attribute and strategic value of digital systems are being recognized by more enterprises. According to the “2024 China Enterprise Digital Transformation White Paper”, 78% of high – growth enterprises list the construction of digital systems as a “strategic priority project”, and the correlation between their system investment and business growth is as high as 63% (the industry average is 41%). This shows that when enterprises break out of the narrow perception that “a tool is just an ordinary tool” and deeply integrate the system with strategy, organization and business, its tool attribute can actually unleash “artifact – level” value. It is not only an efficiency tool, but also the infrastructure for enterprises to build core competitiveness in the digital economy era.

Negative Comments: Cognitive Dislocation and Implementation Deviations Turn Digital Systems into “Costly Decorations” or “Grass – roots Burdens”

Although the tool nature of digital systems is clear, the widespread cognitive dislocations in enterprise practice have severely diluted the value of this tool, and even made it turn to the opposite.

The most typical problems are the dual misunderstandings of the “technology omnipotence theory” and the “system quick – fix theory”. Some enterprises deify digital systems as a magic weapon for “one – click transformation”, believing that introducing systems from international giants (such as SAP and Oracle) can solve all management problems, while ignoring the adaptability between the system and the business. For example, a traditional manufacturing enterprise spent tens of millions of yuan to purchase an SAP system, trying to solve the problems of chaotic production processes and inefficient departmental collaboration through the “advanced system”. However, due to the failure to synchronously optimize the organizational structure (such as the production and procurement departments still operating independently) and the lack of system operation training for employees (front – line workers only received a 2 – day crash training), after the system was launched, employees still used paper documents to record production data and then manually entered them into the system, resulting in a data lag rate of up to 40%. Eventually, the system became a “show – off project”. This kind of thinking that “emphasizes technology and ignores adaptability” essentially turns the system into a “mythical symbol” rather than a tool to solve practical problems.

Secondly, the “fragmented introduction theory” leads to system internal consumption. Many enterprises lack overall planning in digital construction. Each department independently introduces independent systems to quickly solve local problems, ultimately forming “data islands” and “process fragmentation”. The case of a certain retail enterprise is very representative: The marketing department introduced System A to track marketing effects, the membership department introduced System B to manage customer points, and the inventory department introduced System C to monitor warehousing. The data of the three systems is not interoperable, resulting in front – line employees having to repeatedly enter membership information and order data in different systems, increasing the daily operation time by 2 hours, and the efficiency actually decreased. This “go – it – alone” system introduction model essentially downgrades the system to a “departmental tool” rather than an enterprise – level “collaborative tool”, ultimately turning the digital system from an “efficiency – enhancing weapon” into a “grass – roots burden”.

A deeper contradiction lies in the cognitive gap between “tool – making” and “tool – using”. Software suppliers, in order to promote sales, often over – package the “technological advancement” (such as emphasizing concepts like AI and big data) and “standardized best practices” of the system, while deliberately downplaying the difficulty of adapting the system to the actual business of the enterprise. The enterprise’s business departments, as the actual users, are more concerned about “whether it can solve immediate problems” and lack an understanding of the long – term value and potential of the system. They may even resist the change due to concerns about changing the existing work mode. For example, a software company promoted an “intelligent dispatching system” to a logistics enterprise, claiming that it could reduce transportation costs by 15%. However, it did not fully investigate the enterprise’s transportation routes (mostly rural roads with weak GPS signals) and the drivers’ operating habits (some drivers only used basic functions). As a result, after the system was launched, it was collectively resisted by the drivers due to inaccurate positioning and complex operations. This kind of dislocation where “tool – makers draw big pictures and tool – users fall into pits” further exacerbates the difficulty of system implementation.

Suggestions for Entrepreneurs: Dynamic Cognitive Adjustment to Evolve the System from a “Tool” to a “Strategic Engine”

In response to the common problems in enterprise digital system applications, entrepreneurs need to establish “dynamic cognitive adjustment ability”, avoiding both deifying the system and underestimating its strategic value. Specifically, they can start from the following five aspects:

1. Clarify the System Positioning: The Tool Is the Essence, and the Strategy Is the Direction

Entrepreneurs need to clearly recognize that the core of a digital system is to “assist the business” rather than “replace the business”. At the architectural level, the system should be regarded as an optimizable and replaceable tool. Avoid blindly pursuing “international giants” or “the latest technology”, and give priority to systems that are highly adaptable to business needs (for example, small and medium – sized manufacturing enterprises can first deploy a lightweight MES system instead of directly implementing SAP). At the strategic level, the system should be regarded as an “engine driving organizational change”. Synchronously plan system construction with business transformation, process reengineering and talent cultivation. For example, when introducing a CRM system, simultaneously adjust the assessment indicators of the sales department (from “sales volume” to “customer lifetime value”) to promote the organization’s transformation towards a “customer – centric” model.

2. Start from Business Needs and Reject “Implementing the System for the Sake of It”

System construction should be guided by “solving specific problems”. Entrepreneurs can adopt the “problem list method”: First, sort out the core pain points in the business (such as inventory backlog and high customer churn rate), and then select or customize system functions around these pain points. For example, a food processing enterprise found that “raw material expiration loss” was a major cost item, so it gave priority to deploying a “raw material traceability and shelf – life management system” instead of implementing a complete ERP system all at once. This “problem – driven” system construction model can not only reduce the initial investment risk, but also quickly verify the value of the system and enhance the team’s confidence.

3. Promote Deep Collaboration between “Business” and “Technology” to Avoid the Disconnection between “Tool – Making” and “Tool – Using”

Entrepreneurs need to play the role of a “bridge” to promote in – depth collaboration between software suppliers (or internal technology teams) and business departments. On the one hand, require suppliers to complete a “business scenario survey” (such as interviewing front – line employees and observing existing processes) before system design to ensure that system functions meet actual operation needs. On the other hand, require business departments to participate in system testing (such as organizing a “user experience group”) and promptly feedback operation pain points (such as complex interfaces and redundant fields) to promote system iteration and optimization. For example, when a chain catering enterprise introduced an “intelligent ordering system”, it involved waiters in the interface design and set frequently used operations (such as “add spicy” and “no ice”) as shortcut keys. After the system was launched, the ordering efficiency increased by 40%, and employees’ resistance was greatly reduced.

4. Establish a “Continuous Operation” Mindset. System Launch Is Not the End

The launch of a system only completes 10% of the “construction”, and the subsequent “operation” is the key. Entrepreneurs need to establish a “system operation team” (which can be composed of business backbones and technical personnel), regularly analyze system usage data (such as function usage rate and data accuracy), identify “sleeping functions” (such as modules with a usage rate of less than 20%) and “inefficient processes” (such as repeated data entry fields), and promote optimization. For example, a cross – border e – commerce enterprise found that the usage rate of the “logistics tracking module” in its ERP system was only 15%. After investigation, it was found that it was because the module required jumping through 3 pages to view information. So, it was optimized to a “shortcut entry on the home page”, the usage rate increased to 60%, and the response time for logistics exceptions was shortened by 50%.

5. Take Small Steps and Replace the “Big and Comprehensive” Radical Approach with “Agile Iteration”

Digital transformation is a long – term process. Entrepreneurs need to avoid the radical strategy of “investing all resources in a large – scale system at once” and instead adopt an agile model of “pilot – verification – promotion”. For example, a clothing enterprise planned to launch an “omni – channel membership system”, but instead of directly covering all stores, it selected 3 pilot stores to test the performance of the system in scenarios such as membership point inter – communication and cross – channel redemption. After collecting problems and optimizing, it gradually promoted the system to other stores. This model can not only reduce the cost of trial and error, but also drive team enthusiasm through “local success” and form a “positive feedback for transformation”.

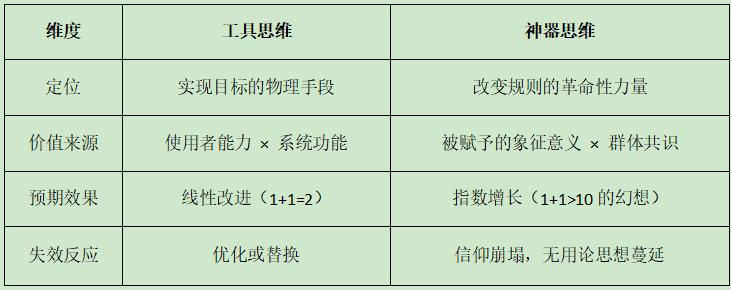

Conclusion: The value of digital systems ultimately depends on how enterprises define them. When it is regarded as a “tool to solve specific problems”, it can improve efficiency; when it is regarded as an “engine driving strategic transformation”, it can reconstruct business models. Entrepreneurs need to abandon the extreme cognitions of “artifact fantasy” and “tool underestimation”, and use a dynamically adjusted mindset to make digital systems truly become the “growth flywheel” for enterprises in the digital economy era.

- Startup Commentary”Three post-2005 entrepreneurs are reported to have secured a new financing of 350 million yuan.”

- Startup Commentary”Retired and Reemployed: I Became Everyone’s “Shared Grandma””

- Startup Commentary”YuJian XiaoMian Breaks Issue Price on Listing: Where Lies the Difficulty for Chinese Noodle Restaurants to Break Through in the Market? “

- Startup Commentary”Adjusting Permissions of Doubao Mobile Assistant: AI Phones Are a Flood, but Not a Beast”

- Startup Commentary”Moutai’s Self – rescue and Long – term Concerns”